Q Model Inventory

Using geometrical relationship from these similar triangles as shown in Fig. Persediaan dapat diartikan sebagai segala sesuatu atau sumber-sumber daya.

Solving Basic Inventory Models Using Excel

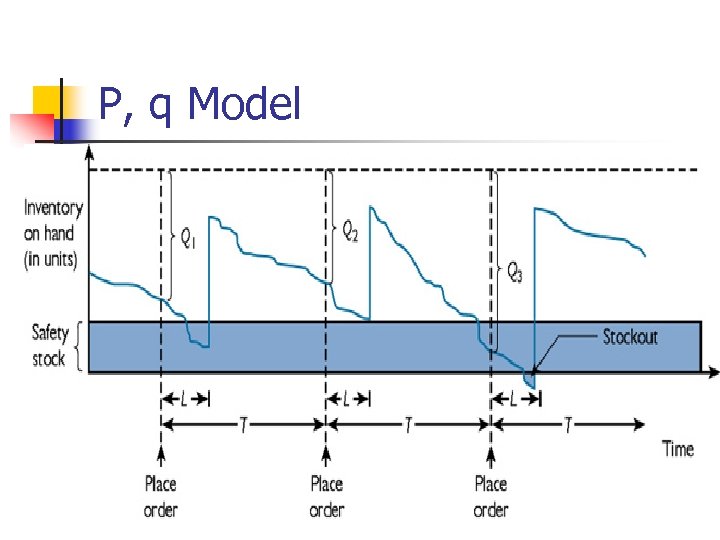

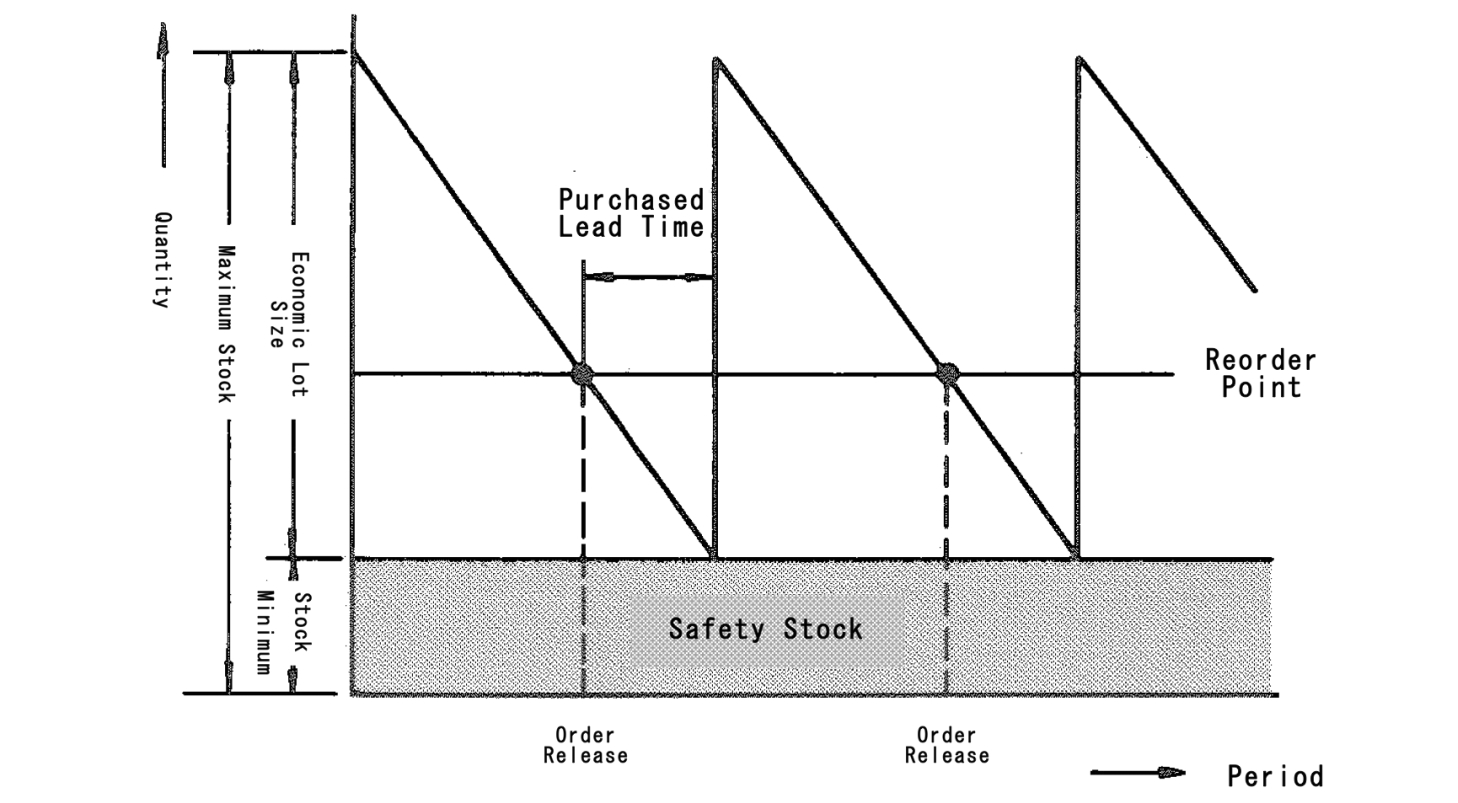

Place a new order whenever the inventory level drops to R.

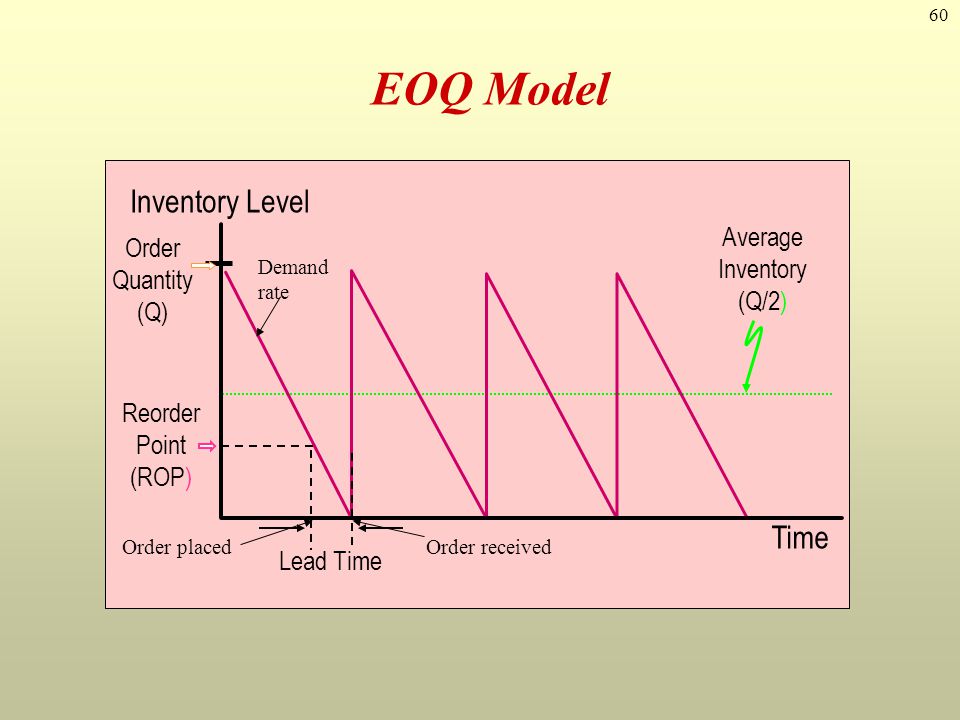

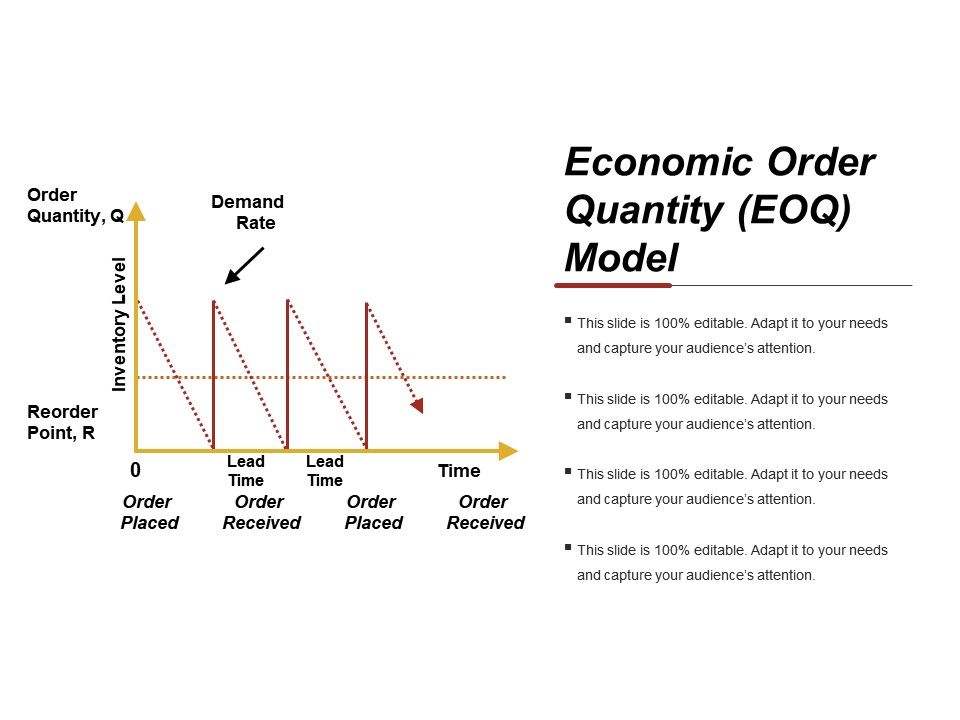

Q model inventory. The EOQ model seeks to ensure that the right amount of inventory is ordered per batch so a company does not have to make orders too frequently and there is not an excess of inventory sitting on hand. That means the orders are placed after a fixed interval of tim. Inventory model is a mathematical model that helps business in determining the optimum level of inventories that should be maintained in a production process managing frequency of ordering deciding on quantity of goods or raw materials to be stored tracking flow of supply of raw materials and goods to provide uninterrupted service to customers without any delay in delivery.

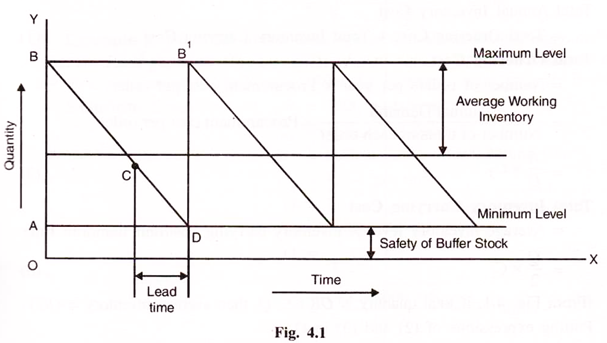

Inventory is reviewed continuously and when inventory drops to a certain prefixed reorder level a fixed quan-. Q Number of Units in each Order Q Optimal Number of Pieces per Order EOQ D Annual Demand in Units for the Inventory Item S Setup or Ordering Cost per Order H Holding or Carrying Cost per Unit per Year The EOQ Model 28 Notes. The maximum ILis Q the minimum is 0 therefore the average ILis Q 2.

Answer 1 of 2. Lot sizeReorder level QR Models ISYE 3104 Fall 2013 Recap. Harris in 1913 to make a proper balance between lot size and setup cost.

P and Q model material inventory control system snack production. Types of Inventory System Q and P Models The term inventory derives from the French word inventaire and the Latin word inventariom which simply means a list of things which are found. Total time of the cycle t t 1 t 2.

INVENTORY MODELS WITH CONTINUOUS STOCHASTIC DEMANDS1 BY SIDNEY BROWNE AND PAUL ZIPKIN Columbia University1 This article is concerned with the r q inventory model where de- mand accumulates continuously but the demand rate at each instant is. The term inventory includes materials which are in raw form or are in process in the finished packaging spares and the others which are stocked in order to. Setting Q as the economic re-order quantity and computing R accordingly is employed this practice may have a substantial cost penalty because Q was not obtained through optimal procedures the problem is explicit expressions for Q and R cannot be obtained 1.

Multi-Period Inventory Models Q model. 16052531575 using inventory probabilistik Q model backorder storage capacity constrain. 1 studied Q R inventory model.

Reorder quantities for Q R inventory models BC Vasconcelos and MP Marques University of Porto Portugal The reorder level R and the reorder quantity Q are the parameters to be decided in a continuous review inventory policy. Raw material inventory planning is. Fixed Quantity Model Fixed Time Period Model with Safety Stock EOQ and Total Cost Graph EOQ and ReOrder Point Number of Units Purchased Units Demanded Single Period Model - Full Marginal Cost Analysis Approach sd sTL Qopt 100000 500 125 1000 20000 000 000 9000 000 15000 20000 15000 11181 9000 20000 15000 000 000 000 000.

Data processing results obtained optimal order for each the coal is as much as 11000 tons Reorder point is as much as 607346 tons safety stock is as much as 1292 tons and total cost of inventory is as much as Rp. Economic order quantity EOQ model economic production lot size EPL model and the Q r model play a vital role in inventory control and to find answers to the above mentioned problems in the industry. Economic order quantity model EOQ was first modelled by Ford W.

Based on the pattern of reviewing current inventory they are further classified. Inventory Decision Issues Demand of various items Money tied up in the inventory Cost of storage space Insurance expense - risk of fire theft damage Order processing costs Loss of profit due to stock outs Inventory Decision Questions THE EOQ MODEL The EOQ Model Cost Curves EOQ Cost Model D - annual demand Q - order quantity S - cost of. Hal ini disebabkan karena nilai persediaan seringkali merupakan porsi yang besar dalam neraca.

Sis the target inventory level determined by the forecasts. Since Annual holding cost Average inventory Annual holding cost per unit Q. Inventory Control Probabilistik Q Model Q Optimal Reorder point Safety Stock 1.

In addition application of both models based on constant rate production capacity so it is important too to investigate materials inventory model if the company widened or production capacity increased. Fixed order quantity R is the reorder point and is based on lead time Land the forecast. T 1 is the time during which demand is met from inventory stock t 2 is the time when shortage occur.

P-model Fixed Period model P-model in inventory control is also known as fixed-period system. Basic EOQ T 2T3T4T time Inventory It d Q T Q Place an order when the inventory level is R. Otherwise youll be putting all your inventory control attention into a product that isnt bringing you the most money.

Inventory Controls Models Start with Inventory Management Systems. Their optimal values can be approached through iterative methods but these are tedious and inconvenient for control. The order arrives after time periods Q was the only decision variable R could be computed easily because D was deterministic Rd Lead time.

Introduction Inventories of raw materials is very important because the raw materials are materials that will help the process of production. Orders are placed multiple times over the entire production cycle. Continuous Review also called Fixed Quantity or Q system.

Inventory rationing in an s Q inventory model with lost sales and two demand classes P Melchiorsl R Dekker2 and MJ Kleijn2 1 University of Aarhus Denmark. The unit holdingcarrying cost H is usually expressed in one of two ways. P model and Q model in inventory are basically different in terms of frequency of ordering and quantity in each order.

MODEL PENGENDALIAN PERSEDIAAN INVENTORY MODEL Pengertian Persediaan inventory Masalah pengendalian persediaan merupakan masalah yang penting dalam fungsi manajerial. The downside to this inventory control model is that you have to categorize the right inventory correctly in order for it to work. Inventory level IL is the quantity on hand which is di erent from inventory position IP which is equal to inventory on-hand plus quantity on order minus backorder if any.

N Number of order placed per year DQ. 2Erasmus University Rotterdam The Netherlands Whenever demand for a single item can be categorised into classes of different priority an inventory rationing policy should be considered. Fixed time period T is the review period.

Derivation Of Eoq Formula Inventory Control Materials Management

2 Inventory Curve For Q R Model With Disruptions Download Scientific Diagram

Economic Order Quantity Eoq Model Inventory Management Models A Tutorial Scm Supply Chain Resource Cooperative Scrc North Carolina State Universitysupply Chain Resource Cooperative Nc State University

Chapter 12 Independent Demand Inventory Management Operations

A Simple Deterministic Inventory Model From The Above Diagram Let Q Download Scientific Diagram

Chapter 20 Inventory Management Lo 20 1 Explain

Chapter 12 Independent Demand Inventory Management Ppt Video Online Download

Inventory Management And Control Ppt Download

What Is The Difference Between The P Model And The Q Model In Inventory Quora

Economic Order Quantity Eoq Model Powerpoint Presentation Examples Powerpoint Shapes Powerpoint Slide Deck Template Presentation Visual Aids Slide Ppt

Fixed Size Ordering System Inventory Control Mrp Glossary Of Production Scheduler Asprova

Posting Komentar untuk "Q Model Inventory"